Introduction

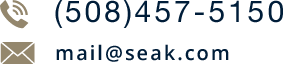

Finite element analysis (FEA) is a technique which helps explain complex technical issues by displaying them in a format which is easy to understand. As such, it can be a potent tool in litigation. In the illustration below, FEA was used to show stresses in a vehicle involved in a collision. The outline of the car is clearly visible, while color shows the stress experienced by its components.

Figure 1: A simulated car crashes into a post. Finite Element Analysis illustrates the stresses and deformation which result from the collision: blue areas have no stress, while the green areas show locations experiencing the highest levels of stress.

What is Finite Element Analysis?

Finite Element Analysis uses a computer to predict how a device will perform, whether in normal conditions or in unusual circumstances such as during accidents. Its history is intertwined with how military technology developed half a century ago.

At the end of World War II, the ENIAC computer successfully calculated artillery firing tables, marking the dawn of the computer age. While aircraft such as the SR-71 Blackbird were being designed with slide rules and wind tunnels, the idea of computer analysis for aerospace development gradually began to seem plausible. Soon the design of jet planes, missiles and aspects of space flight were being influenced by the fledgling FEA technique.

The vast increase in computer power during the reign of Moore’s Law was extremely helpful in making FEA more accessible. During the Cold War, FEA ran on supercomputers to predict the behavior of nuclear weapons. When I started to use FEA two decades ago, it still required painfully expensive computers to achieve useful results. Today, with the advent of cloud computing, vast computational resources can be brought to bear on complex problems at reasonable cost.

FEA can be applied to many situations

An important aspect of FEA is the breadth of its applicability. Learning about the behavior of structures, as shown in figure 1, remains popular. In addition, FEA can be used to answer “what-if” questions involving heat transfer, fluid flow, and electrical components. FEA also helps designers understand whether signals in integrated circuits will be subject to interference, causing the device to fail.

In my consulting practice, clients frequently request FEA of devices which convert electrical energy to motion (transducers). This analysis elucidates both the performance of the device and unwanted side-effects such as heat generation.

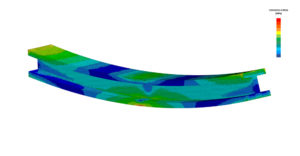

Scientists have discovered mathematical ways to model and predict a great variety of real-world phenomena. What is less widely known is that the equations which govern these phenomena can only be solved for very simple situations. Even a straightforward-looking problem like the bending of a beam (see figure 2) is only soluble with simplifying assumptions about its geometry.

Figure 2: The way a simple I-beam bends under stress can become complex enough to make its solution intractable. Fortunately, FEA makes its behavior easy to understand and visualize.

Common situations which have no straightforward solution are where FEA becomes useful. It cleaves large, complex problems which lack mathematical solutions into a vast number of small, soluble problems. Given enough computer power, this “divide and conquer” approach allows us to design new products, or, in the world of litigation, provide compelling evidence about how an event occurred.

Finite Element Analysis does not care about how complex the shapes and structures are. After solving a huge number of tiny problems, it reconstructs those results into an accurate solution of the original problem.

Where does FEA fit in litigation?

A frequent need in the legal arena is to understand why a product failed. With this information the finder of fact can determine whether there was something wrong with the way the product was designed, if there was a manufacturing defect, or if the product was blameless but used in an inappropriate fashion. Additionally, an FEA expert witness can be used to explore product operation and performance, which may have relevance in IP disputes.

An attractive aspect of FEA is how its output can be expressed in colorful images and animations. Results of an abstruse analysis can be made easy to grasp through the quality of the visual presentation. This can make a finite element analysis expert very helpful.

Conclusion

An expert witness with deep experience in finite element analysis (FEA) can assist in getting to the bottom of a case when the technical aspects are inaccessible to the finder of fact. This technique is very broadly applicable. It requires intense computation, but that is now inexpensively available. FEA results can effectively communicate complex conclusions in the case.

About the author

Dr. Chris Daft is an award winning, Oxford Educated scientist. He is an expert witness and consultant whose areas of expertise include sensors, finite element analysis, signal processing and medical imaging. Dr. Daft has extensive Intellectual Property experience including patent development, licensing, and serving as an expert witness who has given testimony at deposition and trial. He is a serial inventor who holds 24 U.S. Patents with more pending. Dr. Daft holds a BA and MA in Physics from Oxford, and a Doctorate from Oxford in Materials Science. The author may be contacted at:

chris.daft@riversonicsolutions.com

+1 (415) 800-3734 office +1 (408) 806 7525 cell

River Sonic Solutions LLC 2443 Fillmore St #380-4039, San Francisco, CA 94115